2012年11月8日 grinding seeks to reduce materials from roughly one meter cubes of blasted stone to a size where at least 80 percent of the raw material is less than 75 microns. Finish grinding of clinker and other cement ingredients reduces 25 mm clinker balls to

More

PDF The present article deals with the wear of the balls used for the grinding of the clinker in the processes of obtaining cement. Three specimens of... Find, read and cite all the...

More

2013年2月1日 Ball mill is commonly used for grinding cement clinkers. The analysis of feed size reduction in ball mill using the concepts of specific rate of breakage and breakage

More

2023年10月23日 Engineering. Manufacturing Engineering. Material Machining. Grinding. Article PDF Available. A study of different grinding aids for low-energy cement clinker

More

Grinding process of clinker was carried on with a laboratory scale ball mill by varying different type of grinding additives and dosage while the operating conditions of the mill

More

2013年2月1日 To investigate the effects of grinding media shapes on the grinding kinetics of ball mill cement clinker, the grinding effects with ϕ20 mm balls and ϕ20 × 20 mm

More

Grinding ball Allmax I ® (11-13% chromium content) is particularly suitable for cement grinding (raw material and clinker), in particular in the 2nd and 3rd chamber of a tube mill

More

2022年8月18日 Discrete Element Methods (DEM) is a numerical tool consolidated to the simulations of collisions in particulate systems. In this paper, the method was used to

More

2023年6月27日 this paper, the method was used to study the collisions between grinding media and grinding media and walls in ball mills, which is the most used unit operation in

More

2024年1月31日 These balls are typically made of steel or other materials and come in various sizes and shapes. They are placed inside grinding mills or ball mills, where they help break down materials by exerting force through collisions and friction, facilitating the grinding process. Grinding media balls are essential for achieving the desired particle ...

More

2013年2月1日 The effects of balls and cylinders on the clinker's specific rate of breakage were investigated. The results showed that the specific rate of breakage provided by cylinders is higher than that of balls. − 2.00 + 1.70 mm is an optimum feed size for 20 mm diameter balls and 20 × 20 mm diameter cylinders.At that feed size, the value of Si is

More

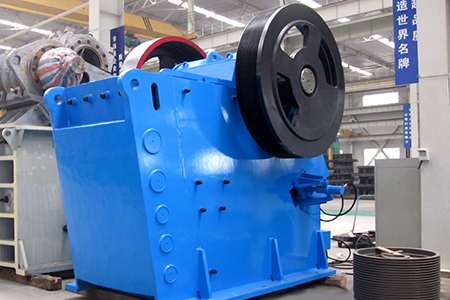

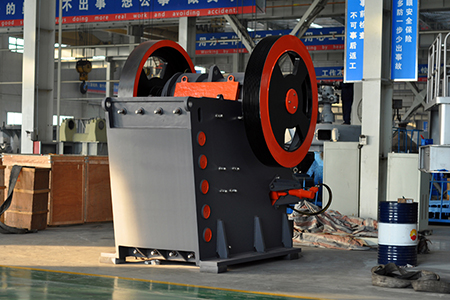

2023年10月19日 It relies on the use of steel balls to crush and grind the clinker. Ball mills are often used for grinding cement clinker into a fine powder before it is mixed with other materials to produce cement. Vertical Roller Mill (VRM): Vertical roller mills are increasingly popular in modern cement plants. They use rollers and a table to grind clinker ...

More

2023年6月27日 this paper, the method was used to study the collisions between grinding media and grinding media and walls in ball mills, which is the most used unit operation in clinker grinding, the majority component of the cement. Amongst the variables that aect the dynamics of the solids in the mills and, consequently, the nal granulometric distribution ...

More

2019年6月22日 Another current trend is the use of technological additives used in the cement grinding process, also known as grinding additives (GA). These are components that improve mill performance by reducing specific energy consumption and increasing cement flow during transport and processing, as well as optimizing the clinker factor [ 4 , 3 ].

More

2020年2月1日 Nowadays, ball mills are used widely in cement plants to grind clinker and gypsum to produce cement. In this work, the energy and exergy analyses of a cement ball mill (CBM) were performed and ...

More

3 天之前 Clinker is a nodular material produced in the kilning stage during the production of cement and is used as the binder in many cement products. The lumps or nodules of clinker are usually of diameter 3-25 mm and dark grey in color. It is produced by heating limestone and clay to the point of liquefaction at about 1400°C-1500°C in the rotary ...

More

2018年2月1日 Ball mills for fine grinding cement clinker and additives are widely used around the world. To improve the efficiency of a ball grinding the ball mills are transferred in closed circuit with air ...

More

2022年10月14日 At the second and third stages, grinding balls with diameter of 15 to 100 mm are used as a grinding tool. According to VNTP 06-91 (Departmental Norms of Production Engineering) [], the rates of consumption of grinding balls during the production of 1 t of cement were specified, including for the first chamber of the mill, consumption of

More

The ore is placed in a ball mill, and the grinding balls inside the mill help break down the ore into smaller pieces, which can then be processed further to extract the desired minerals. Cement Industry: In the cement manufacturing process, grinding balls are used in cement mills to pulverize clinker (a mixture of raw materials) into a fine ...

More

2010年1月1日 A decrease in both clinker factor (up to 15.8%) and grinding energy ( up to 4.5%) can be simultaneously achieved through substitution of clinker with pozzolan materials with lower Mohs hardness ...

More

You've already forked sbm 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

More

2015年7月31日 A 22 L laboratory grinding ball mill operating at 75 rpm rotational speed was used for the grinding of the seashell materials. ... ball mills are widely used in cement plants to grind clinker and ...

More

2021年5月24日 Abstract The surface topography’s subsurface layer condition and the wear elements of balls operated in the mills using wet and dry grinding are studied. The factors that determine the tendency for products to increase its level of wear and cracking during operation have been revealed. Measures have been developed, and its implementation

More

2024年2月22日 Ceramic grinding balls boast exceptional wear resistance, significantly extending their service life and reducing the need for frequent replacements. This durability also means less contamination of the ground materials, a crucial factor in pharmaceuticals and food processing. Steel balls, while durable, tend to wear more quickly in high-impact ...

More

2023年10月23日 A commercial grinding additive, triethanolamine (TEA), and two industrial grinding aids (GAA079 and GAA088) were compared by ball milling tests, with additions of 0.05, 0.25, 0.50 and 1.00 wt%.

More

Coal utilisation in the cement and concrete industries. G. Schumacher, L. Juniper, in The Coal Handbook: Towards Cleaner Production: Coal Utilisation, 2013 15.3.1 Make-up of Portland cement. Portland cement is a fine powder produced by grinding Portland cement clinker (more than 90%), a limited amount of gypsum (calcium sulphate dehydrate –

More

types of mills used for clinker milling grelck . Grinding Mill For Cement Clinker Processing EXODUS Cement mill overview a cement mill is the equipment that used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is cement most cement is currently ground in ball mills cement clinker is usually Chat Now ; Basic Introduction of

More

Mill balls are an essential component of the ball milling process, which involves the use of a rotating cylindrical vessel filled with large pieces of material, such as ore, ceramic, or metal balls, to crush and grind the material into fine powder.The type and quality of the mill balls used in the process play a significant role in determining the efficiency and effectiveness

More

2. The comparative grindability test demonstrates grindability differences between clinkers with different microstructures, simulates the mechanics of ball mill grinding, and is an easy test to perform. 3. Interpretation of clinker microstructure can be made less subjective by inserting observations into grindability equations. Corporate Authors:

More