2021年4月27日 industries andcontinue to operate with old generation classifiers, their maintenance sometimes neglected. This in combination with an inefficient operation

More

2018年7月1日 Cement manufacturing is a process that combines varieties of unit operations including raw meal handling, pyrometallurgy and comminution. Comminution

More

2016年10月5日 Abstract. In this chapter an introduction of widely applied energy-efficient grinding technologies in cement grinding and description of the operating principles of the

More

2001年11月1日 Modelling cement grinding circuits I-t81 CONCLUSION Simulation is a valuable technique to handle all the operating and design variables in a cement grinding

More

2016年11月1日 The paper focusses on improving the energy utilization of a cement grinding circuit by changing the flow sheet of the process. The circuit was comprised of

More

2019年4月30日 The Cement Plant Operations Handbook – Seventh Edition 6. Cement milling Finish milling is the grinding together of clinker with some 3-5 per cent gypsum,

More

2017年10月27日 INTRODUCTION. The VRM is a type of grinding mill integrated with multi functions such as grinding, drying and separation, used for grinding of coal, petroleum

More

2016年12月9日 Schretter Cie, in cooperation with Köppern, developed a concept to integrate a combined air classifier in the existing plant. The upgraded flowsheet of the

More

2021年3月12日 efficient grinding systems available for the cement and mineral industry, including vertical roller mills (VRM), high-pressure grinding units (HPGR) or simple roller

More

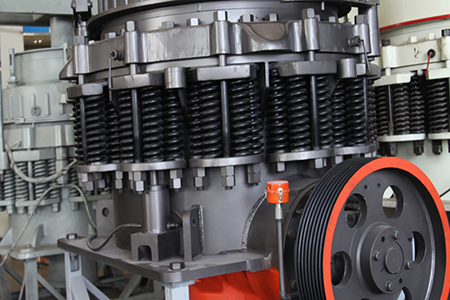

1. Optimization of the Cement Ball Mill Operation. Optimization addresses the grinding process, maintenance and product quality. The objective is to achieve a more efficient

More

2001年11月1日 Abstract. Modelling and simulation studies were carried out at 26 cement clinker grinding circuits including tube mills, air separators and high pressure grinding rolls in 8 plants. The results reported earlier have shown that tube mills can be modelled as several mills in series, and the internal partition in tube mills can be modelled as a ...

More

During heat up there should be a sufficient air flow through the mill to force the heat transfer to the grinding part – forced convection. A sufficient air flow will result in a mill differential pressure of> 5mbar. The duration of

More

classifier equipment operation cement grinding. Oct 15, 2014 Cement grinding operations demand these chemicals in order to improve its energy efficiency As it is a dry grinding environment, more benefits are observed compared to wet grinding applications Regarding to the explanations on particlechemical interaction, so many studies have been ...

More

Vibration velocity at mill gearbox [mm/s]. Power consumption of mill motor with span [kW or alternatively A] Power consumption of system fan [kW] Mill outlet temperature [°C]. Tension pressure [bar] Classifier speed [rpm] Fineness of product [Residue on 90µm sieve , Blain, moisture] Amount of water injection [l/h]

More

Cement grinding unit cost. Take the annual output of 600,000 tons of large-scale cement grinding station as an example, there are three common options can be recommended: SCHEME 1: roller press + φ 3.2 ×13m ball mill; SCHEME 2: φ 3.8 ×13m closed mill; SCHEME 3: clinker fine crusher + cement roller press+φ 3.2 ×13m ball mill.

More

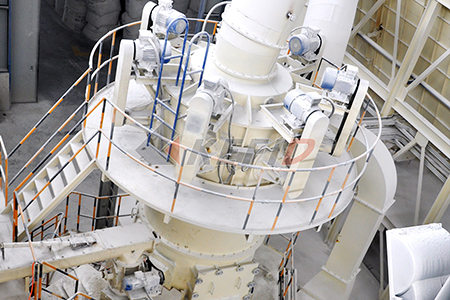

2017年4月1日 Abstract. Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding. The mill combines crushing, grinding, classification and if necessary drying operations in one unit and enables to decrease number of equipment

More

Crusher Classifier Equipment Operation Cement Grinding. Cement Mill Ball Classifier Msrp. Classifier equipment operation cement grinding one cement mill system cm1 produced approximately 65 mth of cement and the second cement mill system cm2 produced approximately 20 mth of cement cm1 is a ball mill in closed circuit with a high efficiency

More

Gebr. Pfeiffer: Grinding equipment for India - Cement Lime Gypsum. The grinding plant will also be capable of producing fly ash cement, in which case dry fly ash will be fed into the classifier separately. ... capacity of 5400 kW, the gearbox for this mill will be one of the largest gearboxes operating in India.

More

2024年1月3日 In the vertical grinding operation process, to form a stable material layer, it is required that the grinding material has a suitable gradation, and more than 95% of the particle size is less than 3% of the roller diameter. Excessive feed size will result in poor grindability. Since the gap between the bulk materials is not filled with enough ...

More

2021年6月15日 The separation process is an integral part of many industrial operations. Most of the present-day plants incorporate dry separation units compared to wet separators, due to scarcity of water and process needs. The VSK separator is a dynamic air classifier widely used in closed circuit with High-Pressure Grinding Rolls (HPGR).

More

MPS 3070 BK coal mill, Jaypee Cement Balaji, India. MPS 180 GC vertical roller mill for the grinding, drying and calcining of gypsum, Knauf Knin, Croatia. MPS 100 GC vertical roller mill for the grinding, drying and

More

4 Modular cement grinding plants around the world. Up to now there are four modular cement grinding plant suppliers on the market. The market leader is Cemengal with a market share of 54% in the period 2012 to April 2021 (Figure 7a). Gebr. Pfeiffer and Loesche each have 21% market share, while Sinoma is responsible for only 4%. However, Gebr.

More

The cement rotary kiln. When operating the vertical roller mill, the operator must control the inlet and outlet air valves to make the air volume of the system in a balanced state, so as not to affect the air pressure at the back end of the rotary kiln. We are AGICO, a professional cement equipment manufacturer and cement plant contractor.

More

2012年6月1日 Grinding in ball mills is an important technological process applied to reduce the. size of particles which may have different nature and a wide diversity of physical, mechanical and chemical ...

More

2021年1月4日 Classifier Equipment Cement Grinding Oparacion. Getting more from the cement ball mill with the fives,plant and the plant operation itself. efficient and correctly adjusted classifiers for the raw meal and cement grinding systems constitute effective means of reducing the spe-cific electrical energy demand in the cement production pro- cess.

More

Serpentine - A greenish mill and air classifier engineering and proven equipment make possible a single source for your complete dry-grinding mill installation.20191126 A mill is a grinder used to grind and blend solid or hard materials into smaller pieces by means of shear. Tìm hiểu thêm

More

2017年4月1日 Abstract. Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding. The mill combines crushing, grinding, classification and if necessary drying operations in one unit and enables to decrease number of equipment

More

2017年9月11日 The results of the grinding tests on cement material together with its breakage results obtained from 2 cm and 4 cm diameter beds were used in the model fitting of the mill by using perfect mixing ...

More