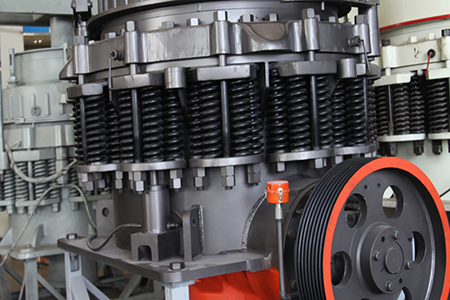

2021年9月24日 (a) A Photo of an attritor ball mill; sketches illustrate (b) ball movement inside attritor ball mill, (c) impact, and (d) shear forces

More

2019年1月1日 There are three major types of high-energy ball mill: the shaker mill, the planetary mill, and the attritor mill. The material processing modes of the shaker mill and

More

2012年2月3日 The objectives of mechanical milling include particle size reduction, mixing or blending, particle shape changes and synthesis of nanocomposite. The typical mill

More

2017年10月10日 Attritor mills are horizontal or vertical drums with an impeller that rotates at very high speeds to agitate and energize the grinding media and powder. These high

More

2021年5月19日 The milling types (shaker, platenary, ball mill, and attritor), the milling materials (vessels, jars, balls, bowls, and vials), the milling size, the ball/powder weight

More

2017年2月21日 High-energy ball mills have been used to prepare energetic materials, including metastable alloys, reactive composites, and fine powders. The three main mill

More

2021年2月2日 HSA (High Speed Attritor) was newly developed in the past few years. These machines feature a unique patented design concept that includes a new grinding

More

2011年7月25日 Production of ultrafine particles by grinding in attritor mill has been successfully applied in chemical, pharmaceutical and mineral processing industries. It

More

2022年9月16日 attritor type, vibratory type, and tumbling type. In the vibratory type of ball mill, grinding of the materials can be performed with vibratory motions with high

More

2022年5月23日 Ball milling is a widely used method to produce graphene and other two-dimensional (2D) materials for both industry and research. Conventional ball milling

More

2024年1月13日 Synthesis of Nanomaterials and Nanocomposites Thakur Prasad Yadav1 ,4 *, Ram Manohar Yadav2 ... This mill is called an attritor or attrition mill and is illustrated in Fig. 2 (a, b). Milling ...

More

The S-1 Batch Attritor is a versatile, reliable, rugged laboratory-size machine designed to meet virtually all lab grinding and dispersing needs—either wet or dry. It allows easy and precise scale-up to production size equipment

More

The Attritor’s design accounts for much of the difference: conventional ball mills turn the entire drum or tank containing the media and the material, while Attritors stir the media in a stationary tank with a shaft and attached

More

2020年12月29日 Attritor fits into the family of mills. For example, ball mills use large media, normally ½” or larger, and run at a low (10-50) rpm. The other mills, such as sand, bead and horizontal, use smaller media (from 1/64” to 1/8”), but run at a very high rpm (roughly 800-1200). High-speed dispersers with

More

2020年12月31日 The Dry Grinding Process. The Attritor dry grinding process is achieved in a stationary tank by means of a rotating shaft and arms that agitate the media into a random state of motion of internal porosity called kinematic porosity. In this expanded condition, the media and particles are free to move, collide and impinge upon each other.

More

Synthesis of Nanomaterials and Nanocomposites Thakur Prasad Yadav1 ,4 *, Ram Manohar Yadav2 ... This mill is called an attritor or attrition mill and is illustrated in Fig. 2 (a, b). Milling ...

More

2024年1月19日 Synthesis of Nanomaterials and Nanocomposites Thakur Prasad Yadav1 ,4 *, Ram Manohar Yadav2 ... This mill is called an attritor or attrition mill and is illustrated in Fig. 2 (a, b). Milling ...

More

2011年7月25日 Attritor mill is a solid-state break-down technique and has been recognised as an efficient grinding equipment for efficient and economical production of nanoparticles [3]. The choice of the equipment for superfine and ultrafine grinding depends on the end-use of product, required product size distribution, purity requirements, and sensitivity ...

More

2019年1月1日 Nanomaterials not only provide us with opportunities to interpret the nature of solid interfaces and to expand our understanding of the structure–property relationship down to the nanoscale regime, but also introduce attractive potentials for scientific and technology applications. ... and the attritor mill. The material processing modes of ...

More

2022年9月16日 attritor type, vibratory type, and tumbling type. In the vibratory type of ball mill, grinding of the materials can be performed with vibratory motions with high frequencies and low amplitudes. The ball’s velocity in the vibratory milling apparatus is much greater than that of planetary ball mill system; there-

More

2001年3月26日 The attritor, or stirred ball mill, is a grinding mill containing internally agitated media. There are quite a few types of attritors; they can be categorized as dry grind, wet grind, regular speed (to 400 rpm) and

More

2001, 2004). Of the above types of mills, only the attritor mill has the highest capacity of powder charge. Accordingly, the attritor milling is employed to synthesize thermal spray feedstock powders used for the fabrication of nanostructured coatings. Fig. 2. Various types of high energy ball mills: (a) attrition mill, (b) vibratory mill, and

More

500 HP IPEC 7000 Attritor. Used 500 HP Attrition Mill. Manfactured by IPEC. Model 7000. 72" diameter X 76" high Milling chamber with 6-rows of high-speed rotating discs with 3" wide x 4" high x 3/8" thick hammers. 4"

More

4 天之前 Attrition mills mechanically reduce solid particles through the intense acceleration of particles against one another in a curved or flat grooved surface called a stator. These mills use a high-speed rotor to create centrifugal forces that facilitate the necessary particle interactions. Rotors' designs can vary, where some include multiple ...

More

2023年8月14日 Synthesis of Nanomaterials and Nanocomposites Thakur Prasad Yadav1 ,4 *, Ram Manohar Yadav2 ... This mill is called an attritor or attrition mill and is illustrated in Fig. 2 (a, b). Milling ...

More

MSE Supplies also can offer industrial attritor stirred ball mills with the volume up to 600L. Please Contact Us for quotation. In addition to attritor stirred ball mills, you can use our Planetary Ball Mills to produce fine powders. SKU MA0807 MA0808 MA0809 MA0810 Container Volume (L) 1 5 10 20 Load Volume (L) 0.35 1.75 3.5 7

More

Attritor ball mill also called stirred ball mill, is a kind of ultrafine grinding equipment with high output and energy saving.. With the development of science and technology, there are more and more applications of ultra-fine powders in industry. From ultra-fine grinding of metal and non-metal raw materials to deep processing of new composite materials, dozens of

More

2014年2月25日 The Attritor is often referred to as a agitated ball mill. ... Mill Media Density : After making the selection on size, some selection must made on density. Sand has a density of approximately 2.65 g/cm3, Sand, which was the most common media in the paint and ink industry in sand mills for some time, has sufficient mass to disperse most pastes ...

More

2021年9月24日 (a) A Photo of an attritor ball mill; sketches illustrate (b) ball movement inside attritor ball mill, (c) impact, and (d) shear forces generated by the ball milling media. The equipment is housed in the Nanotechnology and Applications Program (NAP), Energy and Building Research Center (EBRC), Kuwait Institute for Scientific Research (KISR).

More